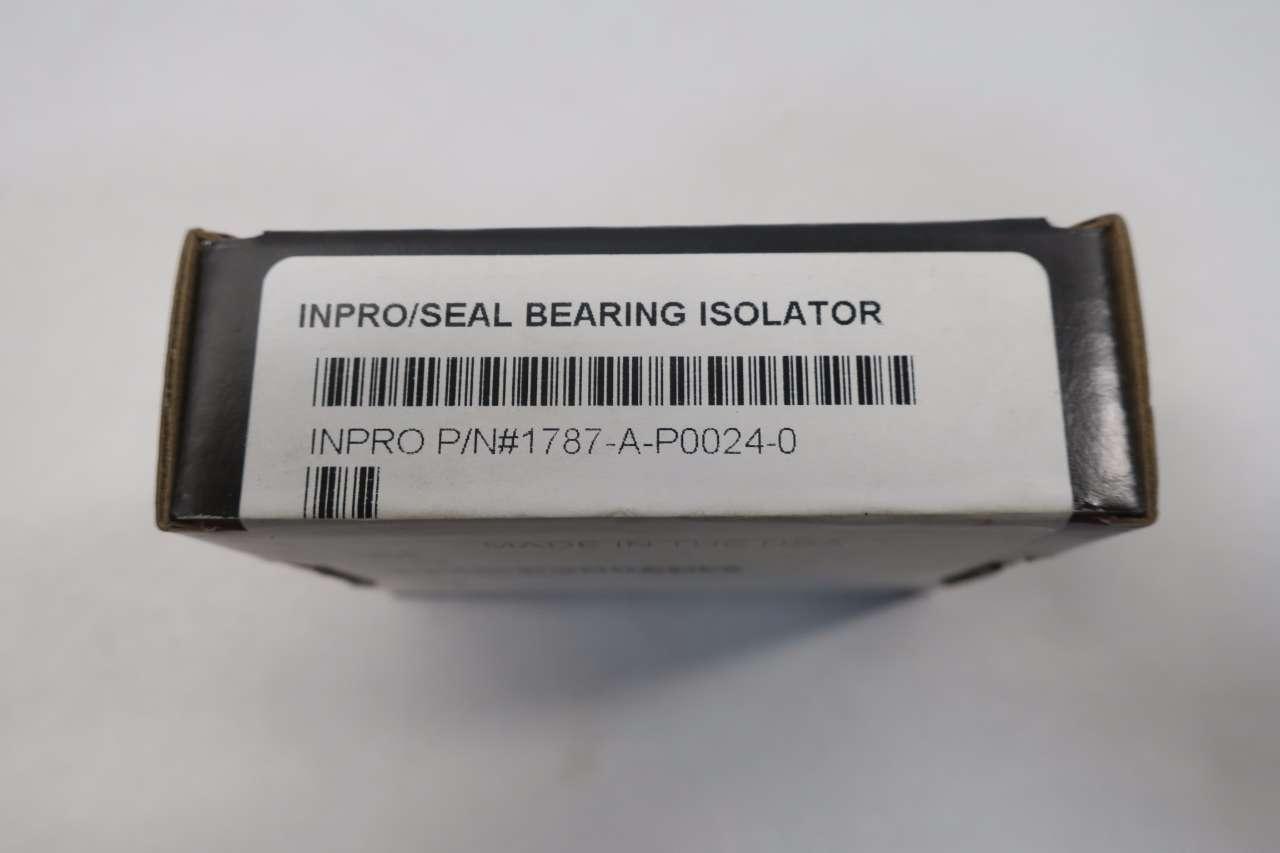

With more than 4,000,000 units operating throughout the world today, the Inpro/Seal Bearing Isolator has been enthusiastically accepted by users and is a standard component in process pumps and electric motors. Protected bearings have proven to run 150,000 hours (17 years) or more, eliminating the need for costly maintenance and repair. The Inpro/Seal Bearing Isolator is a non-contacting labyrinth seal, comprised of a unitized rotor and stator that do not contact one another it does not consume energy and never wears out, and it can be used over and over for many years. Patented in 1977 (#4,022,479), the year he founded Inpro/Seal, the Bearing Isolator (a term coined by Orlowski), for the first time, gave process plants the choice of permanent bearing protection while eliminating the need for continual maintenance. Orlowski developed the worlds first Bearing Isolator. In his quest to find a permanent means of protecting bearings while enhancing and extending the service life of rotating equipment, David C.

Why A Bearing Isolator Outlasts the Equipment It Protects.The Importance of Vapor Blocking Capabilities.Getting Equipment To Run Longer and Increase MTBF (Meantime Between Failure).The Latest In Non-Contacting Technology.How Bearing Isolators Reduce Maintenance Costs.Types of Equipment That Can Be Used With Bearing Isolators.Eliminating the Root Causes of Rotating Equipment Failure.Life Cycles of Bearing isolators, Reliability Factors.What, Precisely, a Bearing Isolator Is And How They Work.Important bearing protection information includes: Written in easy-to-understand language, this literature is a valuable source of information and a useful tool for anyone involved in motor maintenance, repair and operations (MRO), machine tool spindles, turbines, fans, gear boxes, paper machine rolls, pumps, conveyors, shafts, VFDs or other types of rotating equipment used in industrial or process applications. Rock Island, IL (PRWEB) - Inpro/Seal Company, the world's largest producer of industrial bearing isolators, has published literature that provides a detailed overview of its Bearing Isolators and Bearing Isolator-based shaft seals. The literature is written in easy-to-understand language and should prove to be a useful tool for plant maintenance and operations people.

Bearing isolator inpro distributor full#

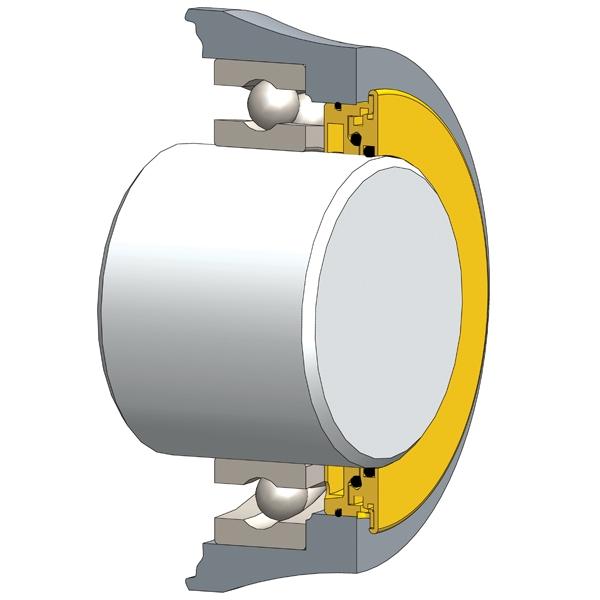

The purpose of the bearing isolator / inpro seal is to keep out leakage and contamination of the oil inside the bearing housing and to keep out dust/dirt from outside the bearing housing which improves the life of the bearing to full potential.īearing lubricant is captured in the inner portion of the labyrinth and directed back into the bearing housing.Inpro/Seal Company, the world's largest producer of industrial bearing isolators, has published literature that provides a detailed overview of its Bearing Isolators and Bearing Isolator-based shaft seals. The cap is shrink-fitted to the outer ring to serve its purpose by holding the inner and outer ring together. There is no mechanical contact between the inner and outer ring while the Isolator is running. The three pieces are assembled into a single unit and axially locked together by O-rings. It also has an outer ring component that is fixed to the bearing housing with a press fit and O-ring gasket. Our Inpro Seal / Bearing Isolator is manufactured in three parts the inner ring rotates with the shaft driven by a tightly fitting drive ring.

However our bearing isolators consist of 3 parts: the cap, inner and outer ring for better performance. A bearing Isolator is a two-part dynamic seal consisting of a stator and a rotor working in conjunction to form a non-contacting compound labyrinth seal – with no wearing parts.

0 kommentar(er)

0 kommentar(er)